Hastelloy B3 (UNS N10675) is a nickel-based high-temperature alloy composed of nickel, molybdenum, cobalt, and other elements, with a nickel content of approximately 65%. Hastelloy B3 (UNS N10675) nickel-based alloy material is a new material improved on the basis of Hastelloy B2, which improves the thermal stability of the material, thereby enhancing its corrosion resistance, while also improving its hot and cold forming performance. In recent years, it has been increasingly applied in the production and manufacturing of chemical equipment. This article will explore the composition, properties, and applications of Hastelloy B-3 in various industries.

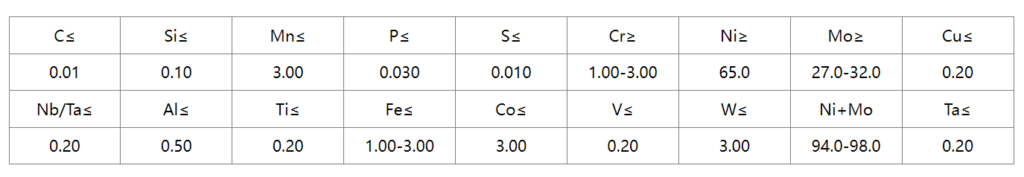

Hastelloy B3 (UNS N10675) – Composition:

Hastelloy B3 (UNS N10675) – Properties:

-

- Excellent corrosion resistance: Hastelloy B-3 can maintain good corrosion resistance under harsh environments such as high temperatures, strong acids, and strong alkalis. This makes it widely used in the chemical, petroleum, marine, and other fields.

- Good mechanical properties: Hastelloy B-3 has high strength, hardness, and good plasticity and toughness, making it suitable for various mechanical parts and manufacturing tools.

- Excellent thermal stability: Hastelloy B-3 can maintain good mechanical properties and corrosion resistance at high temperatures, making it suitable for applications in high-temperature environments.

- Good machinability: Hastelloy B-3 can be processed through various processing methods, such as forging, casting, and cold working.

- Good oxidation resistance: Hastelloy B-3 is not easily oxidized in high-temperature environments and has good oxidation resistance.

- Good resistance to stress corrosion cracking: Hastelloy B-3 is resistant to stress corrosion cracking under stressful conditions, providing good resistance to stress corrosion cracking.

- Good welding performance: Hastelloy B-3 can be easily welded, and the welded material has good performance stability.

Hastelloy B3 (UNS N10675) – Applications:

Hastelloy B-3 is a high-performance material that is widely used in many fields due to its excellent corrosion resistance and high-temperature strength. Its main application areas include but are not limited to:

- Chemical industry: Hastelloy B-3 is widely used in the manufacture of various chemical equipment, pipelines, valves, etc., such as chlor-alkali production equipment, sulfuric acid production equipment, nuclear industry equipment, etc., due to its excellent corrosion resistance and high-temperature strength.

- Petrochemical industry: Hastelloy B-3 is also widely used in the petrochemical industry, where it can be used to manufacture key equipment such as reactors, towers, heat exchangers, and containers. Additionally, in the oil extraction process, Hastelloy B3 can be used to manufacture key components such as downhole tubing and seals, improving oil extraction efficiency and safety.

- Aerospace: Hastelloy B-3 plate has been widely used in the aerospace industry. Due to its excellent corrosion resistance and high-temperature performance, it can be widely used in the manufacturing of key components such as aeroengines, exhaust nozzles, sealing rings, chemical equipment, and flue gas turbines.

- Nuclear industry: Due to its excellent corrosion resistance and high-temperature performance, Hastelloy B-3 is also widely used in the nuclear industry, such as nuclear fuel production equipment and nuclear reactor equipment.

- Other fields: Hastelloy B-3 can also be applied to shipbuilding, marine engineering, medical equipment, and other fields.

- In summary, Hastelloy B-3 alloy is widely used in various fields due to its excellent corrosion resistance and high-temperature strength, providing strong protection for industrial production and equipment operation.

Hastelloy B-3 (N10675) – Varieties, Specifications, and Supply Status:

- Variety classification: Hastelloy B-3 seamless tube, Hastelloy B3 steel plate, Hastelloy B-3 round steel, Hastelloy B-3 forging, Hastelloy B-3 flange, Hastelloy B3 ring, Hastelloy B3 welded tube, Hastelloy B-3 steel strip, Hastelloy B-3 wire and supporting welding materials.

- Delivery status: seamless pipe: solid solution + acid whitening, length can be customized; sheet: solid solution, pickling, trimming; welded pipe: solid solution acid whitening + RT% flaw detection, forging: annealing + grinding; bar in forged and rolled state, surface polished or grinding; strip in cold rolled, solid solution soft state, deoxidation state; wire in solid solution acid pickling disk or straight strip, solid solution straight strip fine grinding state.

Why Choose Huaxiao Alloy?

Thank you for reading our article and we hope it can help you to have a better understanding of the composition, properties, and applications of Hastelloy B3. If you want to learn more about Hastelloy B3, we would advise you to visit Huaxiao Alloy for more information.

As a leading supplier of Hastelloy products across the world, Huxiao Alloy offers our customers high-quality Hastelloy B3 (UNS N10675), Hastelloy D205, Hastelloy G30 (UNS N06030), Hastelloy C-2000, Hastelloy B2, Hastelloy X alloy, Hastelloy C4, Hastelloy C-276, and Hastelloy C22 at a very competitive price.