Hastelloy

Hastelloy is a high-performance nickel-based alloy known for its excellent corrosion resistance and high-temperature strength.

Hastelloy is widely used in a number of applications such as the chemical industry, oil and gas industry, and aerospace industry as a material for the manufacture of critical equipment.

The chemical composition of Hastelloy is carefully proportioned and designed to provide optimum corrosion resistance and mechanical properties.

Hastelloy’s outstanding corrosion resistance and high-temperature strength allow it to maintain stable performance in harsh environments, increasing equipment reliability and safety.

When you choose Hastelloy, you get a reliable, durable and high-performance material that will provide long-lasting protection for your equipment and projects.

Grades of Hastelloy

Hastelloy Product standards Datasheet

| Grades | Plates (ASTM/ASME) | Bars (ASTM/ASME) | Seamless Pipe (ASTM/ASME) | Welded Pipe (ASTM/ASME) | Fittings (ASTM/ASME) | Forgings/Flanges/Valves (ASTM/ASME) |

|---|---|---|---|---|---|---|

| Hastelloy B-3 | SB333/B333 | SB335/B335 | SB622/B622 | SB619/B619, SB626/B626 | SB366/B366 | SB564/B564 |

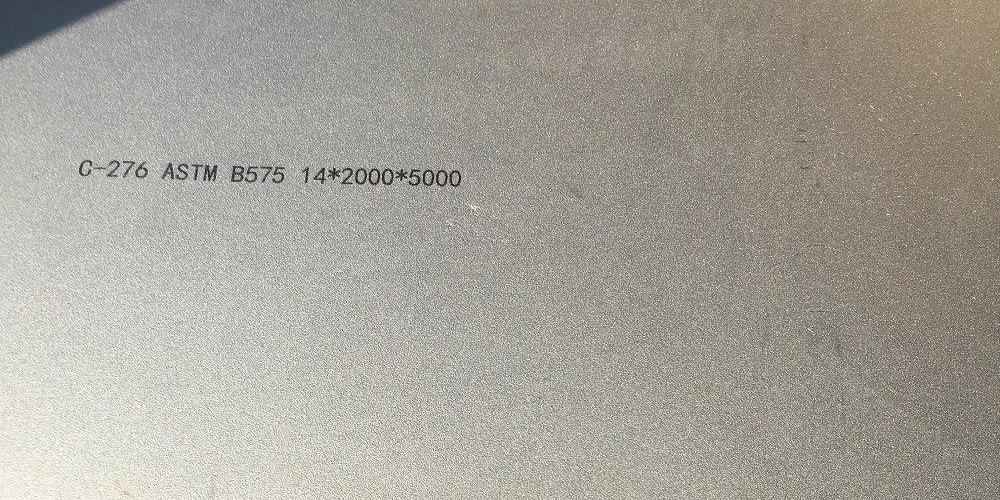

| Hastelloy C-276 | SB575/B575 | SB574/B574 | SB622/B622 | SB619/B619, SB626/B626 | SB366/B366 | SB564/B564 |

| Hastelloy C-22 | SB575/B575 | SB574/B574 | SB622/B622 | SB619/B619, SB626/B626 | SB366/B366 | SB564/B564 |

| Hastelloy C-2000 | SB575/B575 | SB574/B574 | SB622/B622 | SB619/B619, SB626/B626 | SB366/B366 | SB564/B564 |

| Hastelloy G-30 | SB582/B582 | SB581/B581 | SB622/B622 | SB619/B619, SB626/B626 | SB366/B366 | SB564/B564 |

| Hastelloy G-35 | B575 | B574 | B622 | B619/B619, B626/B626 | B366 | B462 |

| Hastelloy X | SB435/B435, AMS 5536 | SB572/B572, AMS 5754 | SB622/B622 | SB619/B619 | B366 | AMS 5754 |

Advantages of Hastelloy alloys

Hastelloy, as a high-performance nickel-based alloy, has the following outstanding unique advantages:

1.Excellent corrosion resistance:

Compared with other metal materials, Hastelloy excels in harsh corrosive environments such as strong acids, strong bases and a variety of organic solvents, providing extremely high corrosion resistance.

2.Excellent high-temperature performance:

Hastelloy has excellent high-temperature strength and stability, able to maintain excellent mechanical properties in high-temperature environments, suitable for high-temperature workplaces in aerospace, automotive and other fields.

3.Good processing performance:

Compared with other difficult-to-machine metal materials, Hastelloy is easy to process, weld and heat-treat, which reduces manufacturing difficulties and costs.

4.Wide range of applications:

Due to its excellent corrosion resistance, high-temperature strength and good processing performance, Hastelloy is widely used in the chemical industry, oil and gas industry, aerospace industry, automotive industry and other fields.

5.Stable long-term performance:

Compared with other metal materials, Hastelloy can maintain long-term stable performance in a variety of complex environments, ensuring the reliability of equipment and systems.

In summary, Hastelloy has outstanding advantages such as excellent corrosion resistance, excellent high temperature performance, good processing performance, wide range of applications and stable long-term performance, which makes it an important material in the industrial field.

FAQs about Hastelloy Alloy

Yes, Hastelloy is an alloy. It is a trademark name for a series of corrosion-resistant nickel alloys produced by Haynes International. These alloys are primarily known for their outstanding resistance to corrosion in severe environments and high temperatures.

Whether Hastelloy is better than stainless steel depends on the application. Hastelloy offers superior corrosion resistance, particularly in environments that are acidic, oxidizing, or contain chlorides. This makes it more suitable for chemical processing environments than many stainless steels. However, stainless steel is generally more cost-effective and sufficiently resistant for many common applications, making it a better choice for general use.

Hastelloy C276 is a nickel-molybdenum-chromium superalloy with an addition of tungsten designed to have excellent corrosion resistance in a wide range of severe environments. The high nickel and molybdenum contents provide good corrosion resistance in reducing environments, while the chromium content provides resistance to oxidizing media.

No, C276 is not an Inconel. It is a type of Hastelloy. While both Hastelloy and Inconel are nickel-based superalloys, they are distinct brands with different chemical compositions tailored for specific applications as mentioned earlier.

Yes, alloy C22 is a Hastelloy. It is specifically designed to resist a wide range of aggressive chemicals, including chlorides, and is often used in applications where C276 would also be appropriate.

Hastelloy C2000 and C276 differ primarily in their chemical composition. C2000 includes a significant amount of copper (approximately 1.6%), which improves its resistance to sulfuric acid, one of the most common industrial acids. C276, while also highly resistant to various chemicals, lacks this level of copper, making C2000 more suitable for environments where sulfuric acid resistance is crucial.

Hastelloy C276 offers several advantages:

- Outstanding corrosion resistance in a wide range of both oxidizing and reducing environments.

- High resistance to pitting and crevice corrosion.

- Ability to withstand stress corrosion cracking and oxidizing atmospheres up to 1900°F (1038°C).

- Excellent resistance to sulfuric, hydrochloric, and phosphoric acids and various organic acids.

- Versatility in terms of applications, making it useful in industries such as pharmaceutical, oil and gas, and chemical processing.