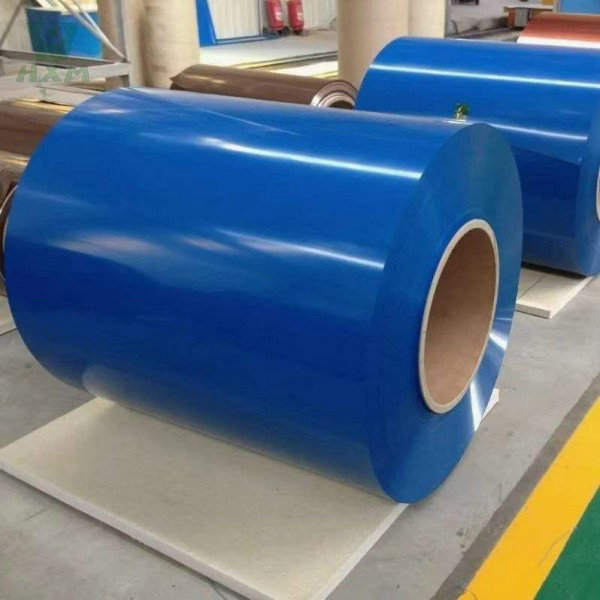

Pre-Painted Galvanized Steel Coil / Sheet / Plate (PPGI/PPGL)

Huaxiao-Alloy’s Pre-Painted Galvanized Steel combines dual-layer protection: a zinc-based metallic substrate (GI or GL) with advanced polymer coatings – engineered to withstand UV degradation, chemical exposure, and mechanical stress while maintaining color integrity for 20-40 years. Precision-formulated for façades, appliances, and specialty enclosures where performance and aesthetics converge.

1. PRODUCT SPECIFICATIONS & ARCHITECTURE

Base Material Options

| Substrate | Standard | Coating Mass | Key Attributes |

|---|---|---|---|

| Galvanized (GI) | ASTM A653 | Z60-Z275 (60-275g/m²) | Cost-effective, weldable |

| Galvalume® (GL) | ASTM A792 | AZ60-AZ150 (60-150g/m²) | 3-5x cut-edge corrosion resistance |

| Zinc-Al-Mg (ZM) | EN 10346 | AZ100-AZ200 (100-200g/m²) | Self-healing scratches, salt spray >2,000hrs |

Coating System Structure

1. Steel Substrate (0.3-3.0mm)

2. Metallic Coating (Zinc/Al-Zn/Zn-Al-Mg)

3. Chromate Conversion Layer (≤15mg/m² Cr⁶⁺-free)

4. Primer (5-8µm): Epoxy/Polyester/Polyurethane

5. Topcoat (15-25µm): PVDF/SMP/Polyester/Siliconized Polyester

6. Clear Coat (Optional): Anti-graffiti/UV-filter

2. COATING PERFORMANCE MATRIX

| Coating Type | Gloss (%) | Color Retention (10y) | Salt Spray (hrs) | QUV Resistance | Max Temp |

|---|---|---|---|---|---|

| Polyester (PE) | 20-80 | ΔE≤5 | 500-800 | 1,000h | 100°C |

| SMP (Silicone Modified Polyester) | 15-50 | ΔE≤3 | 1,000+ | 2,000h | 120°C |

| PVDF (70% PVDF) | 10-40 | ΔE≤2 | 1,500+ | 3,000h | 140°C |

| Fluoropolymer (FEVE) | 40-90 | ΔE≤1 | 2,000+ | 5,000h | 180°C |

ΔE = Color shift per ASTM D2244 | QUV = ASTM G154 Cycle 4

3. MECHANICAL & PHYSICAL PROPERTIES

| Property | Test Method | Typical Value | Industry Impact |

|---|---|---|---|

| Adhesion | ASTM D3359 (Cross-cut) | Class 5B | Survives forming/stamping |

| Pencil Hardness | ASTM D3363 | 2H-4H | Scratch/mar resistance |

| Impact Resistance | ASTM D2794 | 90-150 kg·cm | Withstand hail/impact |

| Flexibility (T-Bend) | ASTM D4145 | 0T-2T | Compatible with roll-forming |

| Solar Reflectivity | ASTM E903 | 80-85% (white) | LEED/EnergyStar compliance |

4. STANDARD PRODUCT RANGE

Architectural Grades (AAMA 2603-2605 Certified)

| Code | Topcoat/Primer | Substrate | Thickness | Finish |

|---|---|---|---|---|

| PPG-AP | PVDF/Polyester | GL AZ90 | 0.5-1.2mm | Matte/Smooth |

| PPG-SMP | SMP/Epoxy | ZM AZ150 | 0.4-1.0mm | Texture/Embossed |

| PPG-FEVE | FEVE/Polyurethane | GI Z180 | 0.3-0.8mm | High-Gloss |

Industrial Grades

| Code | Topcoat/Primer | Substrate | Special Features |

|---|---|---|---|

| PPG-EP | Epoxy/Epoxy | GI Z120 | Chemical resistance (ISO 2812-1) |

| PPG-ECP | Conductive Epoxy/Polyester | GL AZ75 | EMI Shielding (30-60 dB) |

| PPG-FR | Intumescent Coatings | GI Z100 | Fire Rating (ASTM E84 Class A) |

5. INDUSTRY-SPECIFIC SOLUTIONS

| Sector | Application | Huaxiao Solution | Certifications |

|---|---|---|---|

| Building Envelope | Curtain walls, roofing | PPG-AP (PVDF) | AAMA 2605, EN 13501-1 B-s1,d0 |

| HVAC | Air handling units | PPG-SMP (Anti-microbial) | NSF/ANSI 51, ISO 22196 |

| Transport | RV siding, trailer panels | PPG-FEVE (Self-cleaning) | GMW14872, SAE J2334 |

| Appliances | Refrigerator doors | PPG-HG (High-Gloss PE) | IEC 60335-2-24, FDA CFR 21 |

6. HUAXIAO-ALLOY ADVANTAGES

Coating Science Leadership

- Color Consistency: ΔE≤0.8 batch-to-batch (HunterLab Spectrophotometry)

- Edge Protection: Laser-sealed cut edges + touch-up coating systems

- Sustainable Chemistry: Zero Cr(VI), VOCs ≤50g/L (EU Directive 2004/42/CE)

Precision Manufacturing

- In-line coil coating (CPM 120m/min) with IR/UV curing

- 3-stage surface treatment (alkaline clean → rinse → nano-conversion)

- Automated defect detection (AOI with 10μm resolution)

Global Compliance & Support

- Certifications: QUALICOAT Class 2/3, GSB International, NCCA

- Digital Tools: Color matching app, weathering prediction software

- Technical Support: On-site forming/welding training

FAQs: Pre-Painted Galvanized Steel Coil / Sheet / Plate (PPGI/PPGL)

A: Use reverse-roll coating primers with >8% elongation. Huaxiao’s FlexiPrime™ technology enables 180° bending at 0T.

A: PVDF/SMP coatings maintain ΔE≤2 after 10 years Florida exposure (AAMA 2605 data). Avoid standard polyester.

A: 1) Low-pressure wash (<100 bar) 2) pH-neutral cleaners 3) Non-abrasive cloths. Download Huaxiao’s MTC-02 maintenance guide.

A: 10 MT per color with ΔE≤1.0 guarantee (spectrophotometer report included).

A: 20-year warranty against chalking/fading (ΔE≤5) when installed per Huaxiao’s AMI-2024 guidelines.

A: Class A fire-rated panels available with intumescent coatings (ASTM E84 flame spread ≤25).

Pre-Painted Galvanized Steel Coil / Sheet / Plate (PPGI/PPGL)

Need a quote?