For engineers, designers, and procurement specialists navigating material selection, the titanium vs aluminum debate is critical. As Huaxiao-Alloy – a premier global supplier of titanium alloy bar & tube and aluminum profiles/extrusions – we specialize in optimizing material performance. This guide dissects their key differences using scientific data and real-world applications, helping you make informed decisions.

Core Property Comparison: Titanium vs Aluminum at a Glance

| Property | Titanium (Pure/Alloy) | Aluminum (Pure/Alloy) | Winner for Property | Key Implication |

|---|---|---|---|---|

| Density (g/cm³) | 4.51 (Gr2) / ~4.43 (Ti-3Al-2.5V) | 2.70 (1100) / ~2.77-2.89 (7075) | Aluminum | Aluminum offers lighter weight per volume (aluminum weight vs titanium) |

| Tensile Strength (MPa) | 240-550 (CP) / 900-1200+ (Gr5) | 70-150 (1100) / 400-580 (6061) | Titanium | Titanium offers far higher absolute strength (titanium vs aluminum strength) |

| Strength-to-Weight Ratio | Exceptionally High | Very High | Titanium | Titanium excels where strength + lightness are critical (is titanium lightweight) |

| Corrosion Resistance | Outstanding (Passive Oxide Layer) | Good (Anodized alloys better) | Titanium | Titanium resists saltwater, chlorine, acids; aluminum needs protection (galvanized on aluminum? Titanium doesn’t need it) |

| Hardness | Higher (HV ~200-350 CP Gr4) | Lower (HV ~20-120) | Titanium | Titanium resists wear/scratches better (hardness of titanium a plus for watches, tools) |

| Cost (USD/kg) | 40−150+ (mill products) | 3−12 (mill products) | Aluminum | Aluminum offers significant cost savings for non-critical applications |

| Thermal Conductivity | Low (~7-22 W/mK) | High (~130-220 W/mK) | Aluminum | Aluminum dissipates heat effectively (heat sinks, cookware) |

| Machinability | Difficult (low conductivity, gummy) | Excellent (high speeds, good chip control) | Aluminum | Aluminum lowers production costs and cycle times |

| Weldability | Complex (needs inert gas/shielding) | Relatively Easy | Aluminum | Aluminum offers faster, cheaper fabrication |

*(Key Takeaway: Aluminum wins on cost, weight (volumetric), and manufacturability. Titanium wins on strength-to-weight ratio, corrosion resistance, and durability in harsh environments.)*

Titanium Alloy Strip / Precision Strip

Huaxiao-Alloy supplies medical & aerospace-grade Titanium Alloy Strips (0.05–5.0 mm) with ±0.005 mm tolerance. AS9100D & ISO 13485 certified. Custom slitting, annealing, global delivery. Request samples!

Huaxiao-Alloy manufactures high-performance Titanium Alloy Profiles (ASTM B381/ASME SB381) for aerospace, medical, and energy sectors. AS9100D & ISO 13485 certified. Custom sizes, global delivery, competitive MOQ. Request samples now!

Huaxiao-Alloy supplies premium titanium wire and mesh for aerospace, medical, marine, and chemical industries. ASTM/AMS-certified, corrosion-resistant solutions with high-temperature stability. Request a quote today!

Huaxiao-Alloy – Premium titanium alloy pipe & tube manufacturer. ASTM/AMS-certified solutions for aerospace, medical, and chemical industries. Request a quote!

ISO 9001 certified titanium bar manufacturer supplies Grade 5/23/7 round/flat/square bars. Get AMS 4928 compliant 6Al-4V bars with full traceability. Request quote!

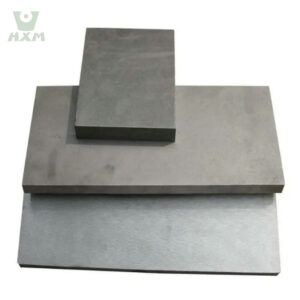

Huaxiao Alloy supplies premium titanium plates, sheets & coils (1/4”, 1/8”, 5mm) for aerospace, armor, and industrial use. TC4, Gr5, and custom alloys available. Free quote & global shipping!

Deep Dive: Performance Factors

1. The Weight Dilemma: Is Titanium Lighter than Aluminum?

- Density Reality: Aluminum (density ~2.7 g/cm³) is inherently ~40% less dense than titanium (density ~4.5 g/cm³).

- Weight Comparison: For the same volume of material, aluminum is significantly lighter (aluminum vs titanium weight).

- Strength-to-Weight Twist: Titanium’s high strength means you can use thinner/lighter structures to achieve equivalent strength as aluminum. Example: A titanium alloy rod at half the weight of an aluminum rod can often bear the same load. Ask: “Which is lighter for my required strength?” (which is lighter titanium or aluminum depends on application)

2. Strength & Durability Battle

- Titanium’s Edge: Grades like Ti-6Al-4V (Gr5) offer ultimate tensile strength exceeding 1000 MPa – comparable to some steels but at half the weight. It resists fatigue, creep, and stress corrosion cracking far better than aluminum alloys.

- Aluminum’s Limit: Even high-strength aerospace alloys (e.g., 7075-T6, strength ~550 MPa) can suffer from corrosion sensitivity and lower fracture toughness. Fatigue life degrades rapidly in aggressive environments.

- Real-World Impact:

- Aircraft: Titanium dominates jet engine parts and high-stress airframe components (titanium weight vs aluminum). Aluminum is preferred for fuselage skins/wings (weight-critical, lower stress).

- Apple Watch Series 10 (46mm/49mm): Titanium vs Aluminum models illustrate this. Titanium offers premium feel, scratch resistance (apple watch strap titanium protection), and greater dent resistance. Aluminum is lighter and cheaper, ideal for sport users (is aluminum or titanium better for apple watch** depends on budget/usage).

3. Corrosion Resistance & Environment

- Titanium: Forms a self-healing oxide layer. Resists seawater, hypochlorite, HCl, HNO₃, wet chlorine. Widely used in chemical processing and marine hardware. No coatings usually needed.

- Aluminum: Forms a passive layer but is vulnerable to pitting in saltwater, strong acids/bases. Requires anodizing or galvanic protection (galvanized on aluminum is a common solution but adds cost). Susceptible to galvanic corrosion next to steel/titanium.

- Huaxiao Tip: Use insulating spacers or anti-seize compounds when joining titanium and aluminum to prevent galvanic corrosion in assemblies.

4. Machining & Fabrication Complexity

- Aluminum: The dream metal for machinists. High speeds, easy chip control, minimal tool wear. Complex aluminum extrusions (profiles) are cost-efficient for frames and structures.

- Titanium: Requires slow speeds, heavy coolant flow, specialized tool geometries. Generates heat rapidly (low thermal conductivity), shortening tool life. Titanium bar and tube fabrication demands expertise – Huaxiao’s precision machining minimizes waste/cost.

5. Cost Analysis: Balancing Budget & Performance

- Raw Material Cost: Aluminum typically costs 1/5th to 1/10th of titanium per kg.

- Total Cost: Factor in:

- Part Lifespan (titanium lasts longer in corrosive/stress environments)

- Weight Savings (titanium can reduce system weight → fuel savings)

- Secondary Processing (painting/anodizing aluminum adds cost)

Example: An aluminum structure may be cheaper upfront, but a titanium structure could save millions in reduced downtime for offshore oil platforms.

Huaxiao-Alloy: Your Strategic Partner for Titanium and Aluminum Solutions

Whether you need high-strength titanium tubing for aerospace or corrosion-resistant aluminum profiles for architecture, Huaxiao-Alloy delivers globally certified quality:

- Dual Expertise: Deep metallurgical knowledge across titanium alloys (Gr2, Gr5, Gr9) & aluminum alloys (6061, 7075, 2024).

- Premium Stock: Ready inventory of titanium bar & tube, aluminum sheet/plate/extrusions in mill finishes.

- Precision Processing: Laser cutting, CNC machining, bending, welding (incl. titanium’s specialized needs).

- Supply Chain Efficiency: Competitive pricing on mill-direct materials.

- Application Engineering: We answer the “Aluminum or Titanium?” question (aluminum or titanium) with data-driven analysis.

The titanium vs aluminum debate has no single winner – only optimal choices based on application:

- Choose Aluminum When: Cost, machinability, thermal conductivity, or minimizing weight per volume is paramount (e.g., consumer electronics casings, heat sinks, structural frames).

- Choose Titanium When: Ultimate strength-to-weight ratio, extreme corrosion resistance, biocompatibility, or long-term durability in harsh environments justifies the cost (e.g., aerospace engines, chemical processing, medical implants, luxury watches).

Huaxiao-Alloy empowers your success. We supply the precise aluminum profiles for your light structures and titanium bar & tube for your mission-critical components – backed by deep technical support and global logistics. Request a quote today and leverage our dual-expertise advantage!

Titanium vs Aluminum in Wearables: Apple Watch Showcase

| Feature | Apple Watch Aluminum | Apple Watch Titanium | Key Difference |

|---|---|---|---|

| Weight (41mm) | ~32-35g | ~45-48g | Titanium ~40% heavier (is titanium heavier than aluminum?) |

| Durability | Anodized surface (scratch-prone) | Brushed Titanium (scratch-resistant) | Titanium wins for abrasion resistance (apple watch aluminum vs titanium scratches) |

| Dent Resistance | Low (soft metal) | High | Titanium handles impacts better |

| Feel/Color | Matte finish (vibrant colors) | Premium metallic sheen (gold titanium, grey) | Titanium offers luxury appeal (difference between aluminum and titanium apple watch) |

| Cost | Lower (399−799) | Higher (699−899+) | Titanium commands premium pricing (aluminum or titanium apple watch budget) |

*(Verdict: Choose Aluminum for lightweight sports use. Choose Titanium for premium feel, durability, and investment value. See also Series 10 Aluminum vs Titanium comparisons on tech sites.)*

A: Aluminum is lighter when comparing the same volume of material (aluminum vs titanium weight). However, titanium’s higher strength often means you need less material for equal performance, potentially leading to lighter components.

A: Yes. Even pure titanium is stronger than standard aluminum. Titanium alloys (Ti-6Al-4V) are 2-3x stronger than the strongest aerospace aluminum (7075-T6). (titanium vs aluminum strength favors Ti).

A: Titanium is vastly superior due to its exceptional corrosion resistance. Aluminum requires careful alloy selection and protective coatings to avoid pitting/crevice corrosion in marine environments.

A: Yes, but take care! Galvanic corrosion can occur. Use insulating materials (plastic/rubber spacers) or isolating fasteners between the two metals. Huaxiao-Alloy provides detailed corrosion avoidance guides.

A: Cost and weight efficiency. Aluminum provides excellent strength-to-weight for large structures like fuselages and wings at a fraction of titanium’s cost. Titanium is used selectively in high-heat/stress zones (engines, landing gear).

A: No. Titanium’s higher hardness makes it significantly more scratch and dent-resistant than aluminum. This is why titanium watches hold their looks longer.

A: Titanium performs better. Standard aluminum weakens above 150°C. Titanium retains strength up to 500-600°C. For heat dissipation (heat sinks), aluminum wins due to its high thermal conductivity.

A: Both are highly recyclable. Aluminum is recycled more widely at lower energy cost. Titanium recycling requires specialized facilities but maintains high material value.