Titanium Alloy

Huaxiao Alloy specializes in manufacturing and supplying aerospace-grade titanium alloy products (plate, bar, tube, wire) with ISO 9001 & AS9100 certifications. We serve industries ranging from medical implants to deep-sea engineering, offering custom sizes, compositions, and surface finishes. Request a free quote within 24 hours!

Why choose Huaxiao-Alloy as your Titanium Alloy supplier?

Highest Quality Steel

Quick Delivery

Professional Service

Flexible payment options

Explore Our Titanium Alloy Product Range

| Product Category | Standard Grades | Key Properties | Applications |

|---|---|---|---|

| Titanium Plates | TC4 (Gr5), TA2 (Gr2), TB6 | Corrosion-resistant, weldable, lightweight | Aircraft skins, chemical reactors |

| Titanium Bars | TC11, Gr23, Ti-6Al-4V ELI | High fatigue strength, biocompatible | Engine components, bone implants |

| Titanium Tubes | Gr9, Gr12, TA10 | High-temperature resistance, ductile | Heat exchangers, marine pipelines |

| Custom Shapes | 3D printing, forged parts | Complex geometries, rapid prototyping | Aerospace brackets, surgical tools |

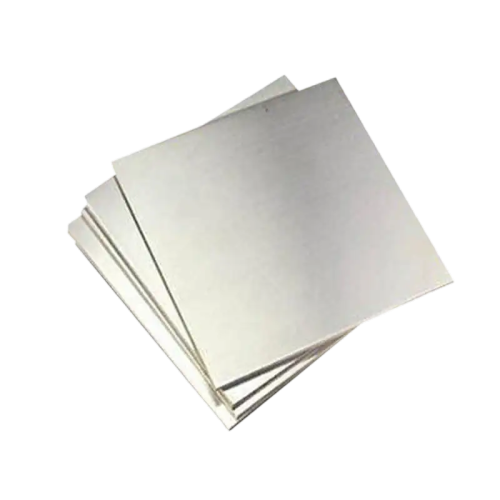

Titanium Alloy Sheet

Gr1 Titanium Alloy Sheet

Gr2 Titanium Alloy Sheet

Gr3 Titanium Alloy Sheet

Gr4 Titanium Alloy Sheet

Gr5 Titanium Alloy Sheet(Ti-6Al-4V)

Gr7 Titanium Alloy Sheet(Ti-0.15Pd)

Gr9 Titanium Alloy Sheet(Ti-3Al-2.5V)

Gr11 Titanium Alloy Sheet(Ti-0.15Pd)

Gr12 Titanium Alloy Sheet(Ti-0.3Mo-0.8Ni)

Gr19 Titanium Alloy Sheet(Ti-0.3Mo-0.8Ni)

Gr20 Titanium Alloy Sheet(Ti-3Al-8V-6Cr-4Mo-4Zr Beta-C)

Gr23 Titanium Alloy Sheet(Ti-6Al-4V ELI)

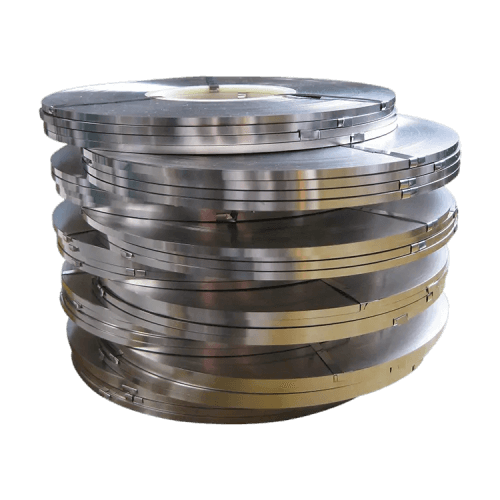

Titanium Alloy Strip

Gr1 Titanium Alloy Strip

Gr2 Titanium Alloy Strip

Gr3 Titanium Alloy Strip

Gr4 Titanium Alloy Strip

Gr5 Titanium Alloy Strip (Ti-6Al-4V)

Gr7 Titanium Alloy Strip (Ti-0.15Pd)

Gr9 Titanium Alloy Strip (Ti-3Al-2.5V)

Gr11 Titanium Alloy Strip (Ti-0.15Pd)

Gr12 Titanium Alloy Strip (Ti-0.3Mo-0.8Ni)

Gr19 Titanium Alloy Strip (Ti-0.3Mo-0.8Ni)

Gr20 Titanium Alloy Strip (Ti-3Al-8V-6Cr-4Mo-4Zr Beta-C)

Gr23 Titanium Alloy Strip (Ti-6Al-4V ELI)

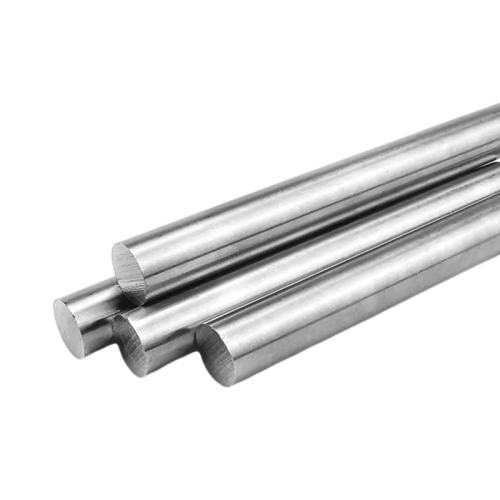

Titanium Alloy Bar

Gr1 Titanium Alloy Bar

Gr2 Titanium Alloy Bar

Gr3 Titanium Alloy Bar

Gr4 Titanium Alloy Bar

Gr5 Titanium Alloy Bar (Ti-6Al-4V)

Gr7 Titanium Alloy Bar (Ti-0.15Pd)

Gr9 Titanium Alloy Bar (Ti-3Al-2.5V)

Gr11 Titanium Alloy Bar (Ti-0.15Pd)

Gr12 Titanium Alloy Bar (Ti-0.3Mo-0.8Ni)

Gr19 Titanium Alloy Bar (Ti-0.3Mo-0.8Ni)

Gr20 Titanium Alloy Bar (Ti-3Al-8V-6Cr-4Mo-4Zr Beta-C)

Gr23 Titanium Alloy Bar (Ti-6Al-4V ELI)

Titanium Alloy Pipe

Gr1 Titanium Alloy Pipe

Gr2 Titanium Alloy Pipe

Gr3 Titanium Alloy Pipe

Gr4 Titanium Alloy Pipe

Gr5 Titanium Alloy Pipe (Ti-6Al-4V)

Gr7 Titanium Alloy Pipe (Ti-0.15Pd)

Gr9 Titanium Alloy Pipe (Ti-3Al-2.5V)

Gr11 Titanium Alloy Pipe (Ti-0.15Pd)

Gr12 Titanium Alloy Pipe (Ti-0.3Mo-0.8Ni)

Gr19 Titanium Alloy Pipe (Ti-0.3Mo-0.8Ni)

Gr20 Titanium Alloy Pipe (Ti-3Al-8V-6Cr-4Mo-4Zr Beta-C)

Gr23 Titanium Alloy Pipe (Ti-6Al-4V ELI)

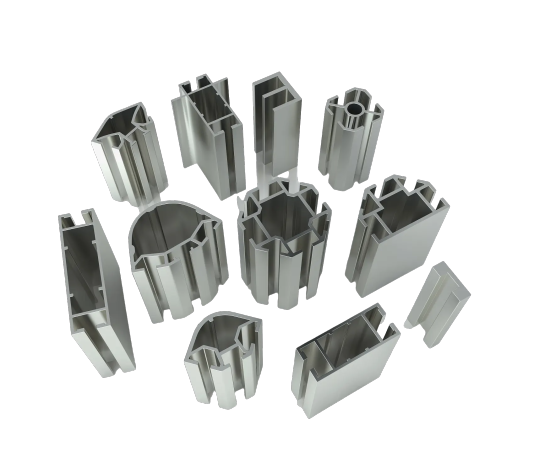

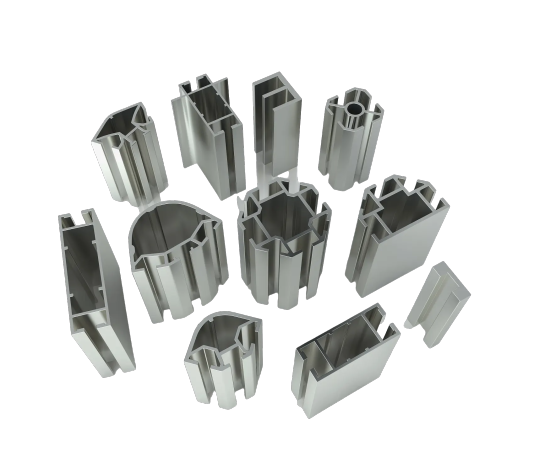

Titanium Alloy Profile

Gr1 Titanium Alloy Profile

Gr2 Titanium Alloy Profile

Gr3 Titanium Alloy Profile

Gr4 Titanium Alloy Profile

Gr5 Titanium Alloy Profile (Ti-6Al-4V)

Gr7 Titanium Alloy Profile (Ti-0.15Pd)

Gr9 Titanium Alloy Profile (Ti-3Al-2.5V)

Gr11 Titanium Alloy Profile (Ti-0.15Pd)

Gr12 Titanium Alloy Profile (Ti-0.3Mo-0.8Ni)

Gr19 Titanium Alloy Profile (Ti-0.3Mo-0.8Ni)

Gr20 Titanium Alloy Profile (Ti-3Al-8V-6Cr-4Mo-4Zr Beta-C)

Gr23 Titanium Alloy Profile (Ti-6Al-4V ELI)

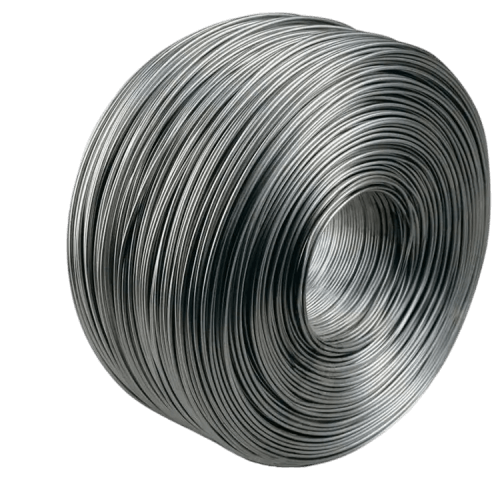

Titanium Alloy Wire

Gr1 Titanium Alloy Wire

Gr2 Titanium Alloy Wire

Gr3 Titanium Alloy Wire

Gr4 Titanium Alloy Wire

Gr5 Titanium Alloy Wire (Ti-6Al-4V)

Gr7 Titanium Alloy Wire (Ti-0.15Pd)

Gr9 Titanium Alloy Wire (Ti-3Al-2.5V)

Gr11 Titanium Alloy Wire (Ti-0.15Pd)

Gr12 Titanium Alloy Wire (Ti-0.3Mo-0.8Ni)

Gr19 Titanium Alloy Wire (Ti-0.3Mo-0.8Ni)

Gr20 Titanium Alloy Wire (Ti-3Al-8V-6Cr-4Mo-4Zr Beta-C)

Gr23 Titanium Alloy Wire (Ti-6Al-4V ELI)

Why Choose Huaxiao Alloy?

✅ 30+ Years Expertise: Titanium alloy R&D leadership since 1992.

✅ Global Certifications: ISO 9001, AS9100, ASTM, AMS, RoHS compliant.

✅ Full Customization: Adjust alloy composition (Al, V, Mo) and dimensions.

✅ Fast Delivery: 15-day standard lead time, expedited orders supported.

✅ Technical Support: Free metallurgical consulting & CAD design services.

Titanium Alloy Solutions for Critical Industries

✈️ Aerospace: TC4 airframe components, Gr23 turbine blades, flame-resistant fasteners.

🏥 Healthcare: Ti-6Al-4V ELI orthopedic implants, TA1 surgical instruments, porous bone scaffolds.

⚡ Energy & Chemical: TA10 desalination pipes, Gr12 nuclear condensers, titanium-palladium valves.

🚢 Marine Engineering: TB8 deep-sea pressure vessels, TA9 ship pumps, cathodic protection systems.

Technical Specifications of Popular Grades

| Grade | Type | Tensile Strength (MPa) | Elongation (%) | Operating Temp. (°C) | Corrosion Resistance |

|---|---|---|---|---|---|

| TC4 | α+β | 895-930 | 10-15 | -250 ~ 400 | ⭐⭐⭐⭐⭐ |

| Gr5 | α+β | 895-930 | 10-15 | -250 ~ 400 | ⭐⭐⭐⭐⭐ |

| TA2 | α | 440-590 | 20-25 | -269 ~ 300 | ⭐⭐⭐⭐ |

| TB6 | β | 1100-1250 | 8-12 | -196 ~ 150 | ⭐⭐⭐ |

FAQs

Gr2 is pure titanium ideal for general corrosion resistance, while Gr5 (TC4) offers superior strength for aerospace and medical applications.

Yes! We provide NiTi alloys (Nitinol) for medical stents and actuators.

Absolutely. We support prototyping and low-volume production (MOQ: 50kg).

Recent Blogs

Titanium Alloy – An Overview

Titanium Alloys: Types, Properties, and Industrial Applications Home 1. Introduction: Why Titanium Alloys Matter Titanium alloys are among the most

A Practical Guide to High Carbon Steel

I’ve been in the steel business for over 25 years, and if there’s one thing I’ve learned, it’s that spec

The Complete Guide to Medium Carbon Steel: What Every Engineer Should Know

Steel has been my world for over two decades. I’ve seen trends come and go, watched new alloys emerge, and

Low Carbon Steel – An Overview

Huaxiao-Alloy supplies premium low carbon steel (mild steel) in ASTM, EN, JIS, and GB grades. Explore properties, applications, comparison tables, and surface processing options. Trusted global supplier with ISO-certified quality and tailored solutions.

Low, Medium, and High Carbon Steel: Everything You Need to Know

1. Choose low carbon steel when cost, weldability, and ductility are top priorities.

2. Opt for medium carbon steel when you need balanced strength and machinability.

3. Select high carbon steel for maximum hardness and wear resistance.

What are the 4 types of stainless steel?

The four primary types are Austenitic (most common, corrosion-resistant, non-magnetic), Ferritic (magnetic, moderate corrosion resistance), Martensitic (high-strength, heat-treatable), and Duplex (combined microstructure, extreme strength/corrosion resistance).