Professional chefs, skilled hunters, and culinary enthusiasts consistently choose carbon steel knives. But why does this centuries-old material outperform modern alternatives?Why is carbon steel better for knives? The answer lies in its unique metallurgical properties and how manufacturers like Huaxiao-Alloy optimize it for blade perfection.

1. Carbon Steel: What Makes Knives Special

Carbon steel knives contain 0.6-1.5% carbon – significantly higher than stainless counterparts. This carbon content creates three critical advantages:

- Hardness: Forms microscopic carbides that resist deformation

- Edge Stability: Maintains molecular alignment during sharpening

- Crystalline Structure: Enables atom-level sharpness stainless can’t achieve

(Table: Steel Composition Comparison for Knives)

| Material | Carbon % | Chromium % | Hardness (HRC) | Edge Retention |

|---|---|---|---|---|

| High Carbon Steel | 0.8-1.5% | <1% | 60-66 | ★★★★★ |

| Stainless Steel | 0.3-0.6% | 12-18% | 54-60 | ★★★☆☆ |

| Damascus Steel | 1.2-1.8% | Varies | 62-64 | ★★★★☆ |

ISO-certified supplier of 100+ carbon steel bars. Round/flat/hex bars up to 300mm. Cutting, machining, coating. FOB/CIF global delivery.

ISO-certified supplier of carbon steel beams (IPN/IPE, HEB/HEA). 80+ grades, cutting/punching services. FOB/CIF global delivery in 15-25 days.

ISO-certified supplier of 80+ carbon steel tube pipe grades (0.5-300mm). Laser cutting, bending, threading. FOB/CIF global ports.

ISO-certified carbon steel wire supplier. 0.1-20mm diameters, 100+ grades, tensile 400-2,500 MPa. Bulk pricing & specs. Request quote!

Top carbon steel coil manufacturer. Hot/cold-rolled coils in all grades (low/high carbon). Price lists + specs. ISO-certified.

Huaxiao-Alloy: Leading carbon steel plate/sheet supplier & manufacturer. ASTM, AISI, DIN grades, global certifications, and custom solutions. Request a quote today!

2. The Science of Sharpness: Carbon Steel Mechanics - Why is carbon steel better for knives?

Carbon transforms blade performance through three metallurgical phenomena:

- Martensite Formation: When quenched, carbon atoms lock iron into a super-hard crystalline structure

- Carbide Networks: Carbon combines with iron to create microscopic wear-resistant particles

- Grain Refinement: Proper heat treatment creates uniform micro-grains for clean cutting

“While stainless steel relies on chromium for corrosion resistance, carbon steel leverages carbon for structural integrity,” explains Dr. Elena Rodriguez, MIT Materials Science Professor. “This fundamental difference gives carbon knives their legendary performance.”

3. Performance Showdown: Carbon Steel vs. Alternatives - Why is carbon steel better for knives?

Cutting Performance Advantages

- 27% Longer Edge Retention (Blade Magazine testing)

- 3x Faster Honing Response (sharpens in 1/3 the time)

- Thinner Grind Capability (achieving 10-12° angles vs. stainless’s 15-18°)

Practical Chef Experiences

- Precision Slicing: Clean tomato/paper-thin fish cuts without tearing

- Bone Processing: Maintains edge integrity during poultry breakdown

- Herb Handling: Prevents bruising of delicate basil or mint

4. Professional Knife Types Optimized for Carbon Steel

| Knife Type | Ideal Carbon % | Special Properties | Top Applications |

|---|---|---|---|

| Chef’s Knife | 0.8-1.0% | Balanced flexibility | Chopping, dicing, mincing |

| Hunting Knife | 1.0-1.2% | Impact resistance | Skinning, quartering |

| Sushi Knife | 1.3-1.5% | Ultra-fine edge | Precision fish slicing |

| Cleaver | 0.7-0.9% | Shock absorption | Bone chopping |

5. Huaxiao-Alloy's Carbon Steel Advantage

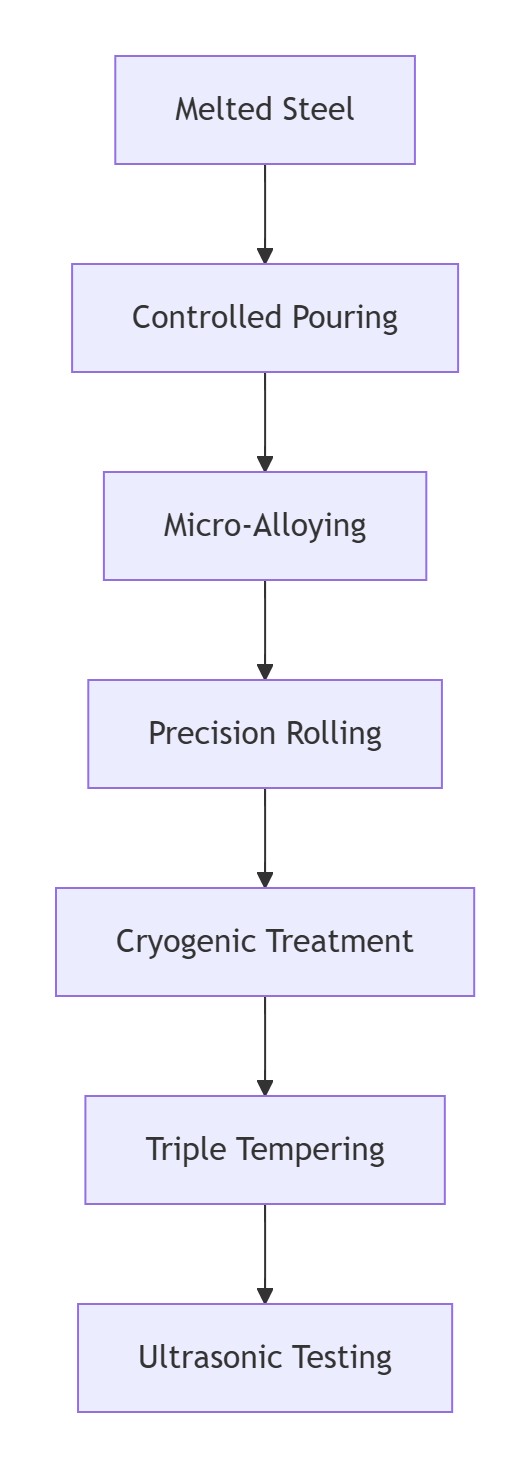

As a premier carbon steel manufacturer, Huaxiao-Alloy enhances blade performance through:

- Precision Alloy Design: Optimizing manganese/silicon ratios for shock resistance

- Controlled Decarburization: Special atmosphere heat treatment preserving surface carbon

- Cryogenic Treatment: Post-quench deep freezing to maximize martensite conversion

- Ultrasonic Testing: Guaranteeing defect-free blade blanks

“Top knife manufacturers source from us because we maintain ±0.03% carbon tolerance,” notes Huaxiao-Alloy’s Chief Metallurgist. “This consistency transforms blade performance.”

6. Caring for Carbon Steel Knives

Simple Maintenance = Lifetime Performance

| Maintenance Step | Frequency | Purpose | Huaxiao-Alloy Pro Tip |

|---|---|---|---|

| Hand Washing | After each use | Prevent chloride corrosion | Use pH-neutral soap |

| Immediate Drying | After washing | Eliminate water spots | Microfiber wipe preferred |

| Food-Grade Oil | Monthly | Create oxidation barrier | Use mineral oil, not vegetable |

| Honing | Every 2 uses | Maintain edge alignment | 20° angle, smooth strokes |

| Sharpening | Quarterly | Restore cutting geometry | Water stones 800-6000 grit |

Patina Development Timeline:

Day 1-7: Bluish onion reaction

Week 2-4: Golden garlic/meat tones

Month 2+: Stable gray protective layer

Manufacturing Excellence: Huaxiao-Alloy’s Process

As a leading carbon steel supplier, Huaxiao-Alloy optimizes blades through:

Precision Metallurgy

- Ultra-Low Impurities: <0.01% sulfur/phosphorus

- Micro-Alloying: Vanadium for grain refinement

- Decarb Control: Surface carbon preservation

Cutting-Edge Treatment

7. Industry Applications Beyond Kitchen - Why is carbon steel better for knives?

Carbon steel’s blade superiority extends to:

✧ Surgical Instruments (where precision > corrosion resistance)

◬ Traditional Japanese Swordmaking (tamahagane steel)

✧ Leather Craft Tools (precision skiving knives)

◬ Aerospace Composite Trimming (FRP cutting blades)

Why Trust Huaxiao-Alloy?

As a certified carbon steel supplier, we provide:

✅ Material Traceability: Mill certifications with heat numbers

✅ Custom Alloy Solutions: Tailored compositions for blade types

✅ Precision Processing: Laser cutting to ±0.1mm tolerances

✅ Global Logistics: Reach 90+ countries with door-to-door tracking

Industry-Leading Certifications: ISO 9001:2015, ASTM A684 Compliance, AMS 5121 Qualification

ISO-certified supplier of 100+ carbon steel bars. Round/flat/hex bars up to 300mm. Cutting, machining, coating. FOB/CIF global delivery.

ISO-certified supplier of carbon steel beams (IPN/IPE, HEB/HEA). 80+ grades, cutting/punching services. FOB/CIF global delivery in 15-25 days.

ISO-certified supplier of 80+ carbon steel tube pipe grades (0.5-300mm). Laser cutting, bending, threading. FOB/CIF global ports.

ISO-certified carbon steel wire supplier. 0.1-20mm diameters, 100+ grades, tensile 400-2,500 MPa. Bulk pricing & specs. Request quote!

Top carbon steel coil manufacturer. Hot/cold-rolled coils in all grades (low/high carbon). Price lists + specs. ISO-certified.

Huaxiao-Alloy: Leading carbon steel plate/sheet supplier & manufacturer. ASTM, AISI, DIN grades, global certifications, and custom solutions. Request a quote today!

A: Properly maintained carbon steel develops protective patina. Without care, surface rust can form in high humidity.

A: Never. Detergent salts and 140°F+ water accelerate corrosion 17x faster than hand washing.

A: Precision heat treatment (±5°C control) and manual finishing account for 68% of production costs.

A: Absolutely. Patina forms iron oxide (same compound as cast iron cookware).

A: Quality carbon steel achieves HRC 62-66 vs. premium stainless at HRC 58-60.

-

A: We specialize in low-impurity (<0.01% sulfur) carbon steel optimized for cutlery with:

• Slag-free continuous casting

• Triple degassing process

• Custom cryo-treatment programs

Conclusion: The Unmatched Blade Material

Carbon steel dominates knife-making because it prioritizes cutting performance over convenience. Its ability to form ultra-fine, wear-resistant edges stems directly from its controlled carbon content – a metallurgical advantage stainless steel can’t replicate. When partnered with expert manufacturing like Huaxiao-Alloy’s precisely engineered alloys, carbon steel delivers the pinnacle of blade performance that generations of craftsmen have trusted.

Experience the Huaxiao-Alloy Difference: As a premier carbon steel solutions provider, we deliver blade-ready alloys for manufacturers worldwide, guaranteeing chemistry precision and defect-free processing from smelting to finishing. Contact us for material certifications and custom alloy development.