Steel has been my world for over two decades. I’ve seen trends come and go, watched new alloys emerge, and witnessed the evolution of manufacturing processes. But if there’s one material that has consistently impressed me with its versatility and reliability, it’s medium carbon steel.

You might wonder why I’m so passionate about what seems like just another type of steel. The answer lies in its remarkable balance. In my years working with Huaxiao-Alloy, I’ve watched engineers struggle with material selection – they need something stronger than mild steel but not as brittle as high carbon varieties. Medium carbon steel fills that gap perfectly.

This isn’t just another technical guide filled with dry specifications. I’m sharing real-world insights from decades of experience, the kind of knowledge you won’t find in textbooks. Whether you’re designing your first gear system or you’re a seasoned engineer looking for a refresher, this guide will give you the practical understanding you need.

Understanding Medium Carbon Steel: Beyond the Textbook Definition

Let me start with something that might surprise you. When I first started in this industry, I thought carbon content was just a number on a spec sheet. I was wrong. That percentage between 0.30% and 0.60% carbon isn’t just a classification – it’s the sweet spot that makes medium carbon steel so useful.

Here’s what happens at the atomic level (and why it matters for your applications): Carbon atoms squeeze into the iron crystal structure, creating what metallurgists call “interstitial strengthening.” Think of it like adding pebbles to a box of marbles – everything gets tighter, stronger, but still manageable.

How It Compares to Its Cousins

I’ve worked with all types of carbon steel, and each has its place. But let me give you the real story, not just the numbers:

Low Carbon Steel (0.05-0.29% C)

•Great for forming and welding

•Cheap and cheerful

•But don’t expect it to handle serious stress

Medium Carbon Steel (0.30-0.60% C)

•The workhorse of industry

•Strong enough for demanding applications

•Still workable with proper techniques

High Carbon Steel (0.61-1.50% C)

•Incredibly hard when heat treated

•Perfect for cutting tools

•But brittle and difficult to work with

I’ve seen too many projects fail because someone chose the wrong carbon content. A client once insisted on high carbon steel for a shaft application because “harder is better.” The shaft cracked under impact loading within a week. We replaced it with AISI 1045 medium carbon steel, properly heat treated, and it’s still running five years later.

The Properties That Matter (And Why)

Forget the textbook definitions for a moment. Let me tell you what these properties actually mean in practice.

Strength: More Than Just Numbers

When we talk about tensile strength of 565 MPa for AISI 1045, that’s not just a number to impress clients. I’ve seen this steel handle loads that would make mild steel cry for mercy. But here’s the thing – strength without toughness is useless. Medium carbon steel gives you both.

Hardness: The Goldilocks Zone

With a Brinell hardness around 163 in the normalized condition, medium carbon steel sits in what I call the “Goldilocks zone” – not too soft, not too hard, but just right for most applications. I can machine it without excessive tool wear, but it’s hard enough to resist wear in service.

The Heat Treatment Game-Changer

This is where medium carbon steel really shines. I’ve taken AISI 1045 from a relatively soft 163 HB to over 50 HRC through proper quenching and tempering. Try doing that with low carbon steel – you’ll be disappointed.

Here’s a real example: We had a customer making agricultural equipment who needed gears that could handle both shock loads and continuous wear. Standard mild steel gears were failing every season. We switched to medium carbon steel with a quench and temper treatment. Those gears are now lasting three seasons with minimal wear.

| Property | As-Rolled | After Heat Treatment |

| Tensile Strength | 565 MPa | Up to 900+ MPa |

| Hardness | 163 HB | 45-55 HRC |

| Toughness | Good | Excellent (when properly tempered) |

Steel Grades: Choosing Your Weapon

After years of working with different grades, I’ve developed some strong opinions about which ones work best for specific applications.

AISI 1045: The Reliable Workhorse

This is my go-to recommendation for 80% of applications. Why? It’s predictable. I know exactly how it will behave during machining, heat treatment, and in service. The 0.45% carbon content gives you excellent response to heat treatment without being overly sensitive to cooling rates.

Real-world example: We supply 1045 for crankshafts in small engines. The combination of strength and fatigue resistance is perfect for this application. I’ve never had a failure report on properly heat-treated 1045 crankshafts.

AISI 1050: When You Need That Extra Edge

The higher carbon content (0.50%) makes this grade slightly harder and stronger than 1045. I recommend it when wear resistance is critical. But be careful – it’s also more sensitive to heat treatment. I’ve seen parts crack during quenching because someone got careless with the cooling rate.

AISI 4140: The Premium Choice

Technically an alloy steel, but it falls in the medium carbon range. The chromium and molybdenum additions make it significantly tougher and give it better hardenability. It’s more expensive, but when you need the best performance, it’s worth every penny.

I remember a project for heavy-duty truck axles. The customer initially wanted to use 1045 to save costs. After explaining the service conditions and showing them failure analysis reports from similar applications, they switched to 4140. No failures in three years of service.

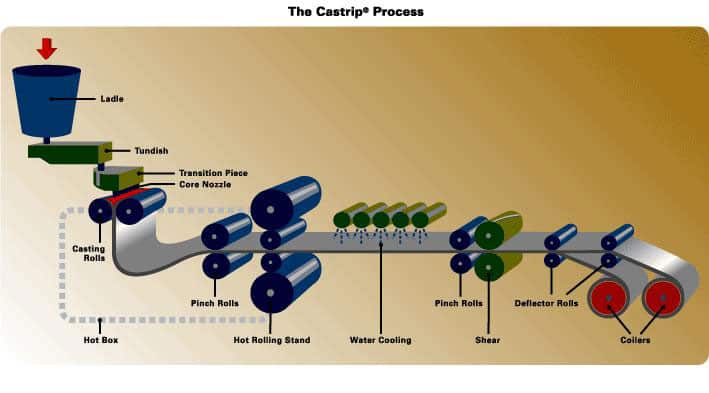

Manufacturing: From Ore to Your Application

I’ve visited steel mills around the world, and the process never stops amazing me. But let me focus on what matters for medium carbon steel.

The critical step happens in the furnace where carbon content is controlled. Too little carbon, and you get mild steel. Too much, and you’re into high carbon territory. The skill lies in hitting that 0.30-0.60% range consistently.

At Huaxiao-Alloy, we work closely with mills that understand this precision. I’ve rejected entire lots because the carbon content was 0.02% outside specification. That might seem picky, but I’ve learned that small variations in chemistry can lead to big problems in performance.

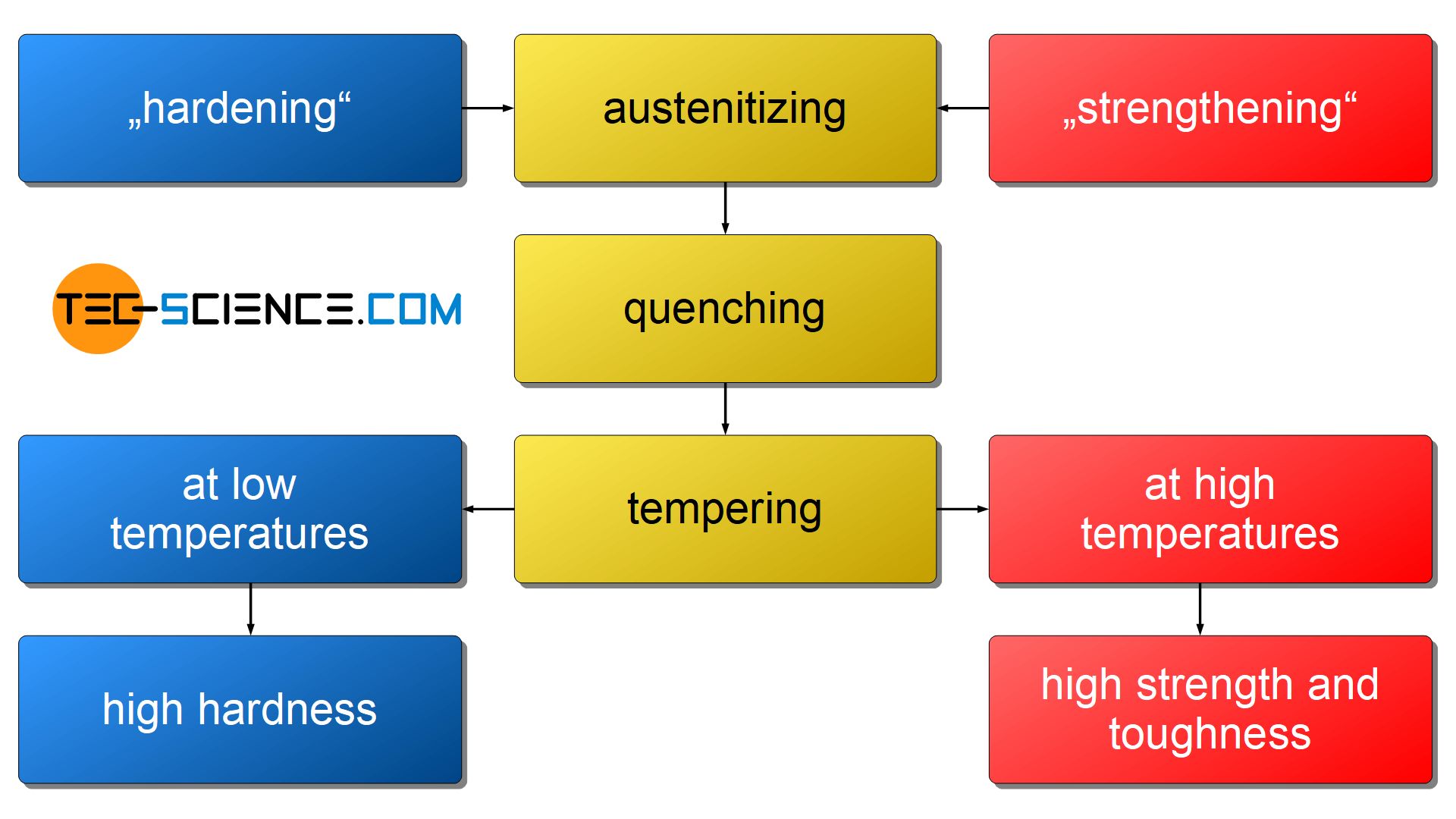

Heat Treatment: Where the Magic Happens

This is where medium carbon steel transforms from good to exceptional. I’ve spent countless hours in heat treat shops, and I can tell you that proper heat treatment is both science and art.

Quenching: The Critical Moment

When you heat AISI 1045 to 820-850°C and quench it rapidly, you’re creating martensite – an incredibly hard but brittle structure. The key is cooling fast enough to avoid pearlite formation but not so fast that you create excessive stress.

I always tell customers: “Quenching makes it hard, tempering makes it useful.” A quenched part is like a loaded spring – full of potential energy but dangerous to use.

Tempering: Finding the Balance

This is where experience matters. The tempering temperature determines your final properties. Want maximum hardness? Temper at 200°C. Need toughness for impact applications? Go to 600°C. It’s all about understanding what your application really needs.

Surface Treatments: Protection and Performance

Corrosion is medium carbon steel’s Achilles heel. But we have solutions.

Phosphating creates a crystalline coating that’s perfect for paint adhesion. I’ve seen phosphated parts last decades in harsh environments when properly painted.

Galvanizing provides sacrificial protection. The zinc corrodes instead of your steel. It’s not pretty, but it works.

Black oxide gives a professional appearance with mild corrosion resistance. Perfect for tooling and automotive components.

Real-World Applications: Where I’ve Seen It Work

Let me share some success stories from my years in the industry.

Automotive: The Demanding Master

Crankshafts are probably the most demanding application for medium carbon steel. They face cyclic loading, high temperatures, and require perfect balance. I’ve worked on crankshaft projects where failure wasn’t an option – literally. Engine failure at highway speeds can be catastrophic.

We use AISI 4140 for high-performance applications and 1045 for standard engines. The key is matching the material to the service conditions.

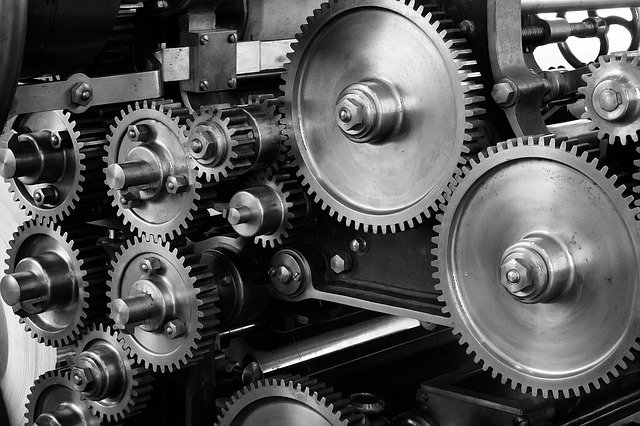

Industrial Machinery: Built to Last

Gears, shafts, and couplings – these are the unsung heroes of industry. I’ve seen 1045 gears run for decades with proper lubrication and heat treatment. The secret is understanding the load cycles and designing accordingly.

Railway: Where Failure Isn’t an Option

Railway applications taught me about fatigue resistance. A railway wheel experiences millions of load cycles. We use carefully controlled medium carbon steel with specific heat treatment to ensure long service life.

Why Huaxiao-Alloy Gets It Right

After working in this industry for decades, I can tell you that not all suppliers are created equal. At Huaxiao-Alloy, we understand that steel is more than just chemistry – it’s about understanding your application and delivering solutions that work.

We don’t just sell steel; we solve problems. When a customer calls with a failure analysis, we dig deep to understand the root cause. Was it material selection? Heat treatment? Design? We figure it out and prevent it from happening again.

Our surface finishing capabilities set us apart. We can deliver parts ready for assembly, not just raw material that needs further processing. This saves our customers time and ensures consistent quality.

Common Questions (And Honest Answers)

Q: Can I weld medium carbon steel?

A: Yes, but it requires more care than mild steel. Preheat to 200-300°C, use low-hydrogen electrodes, and post-heat treat to relieve stresses. I’ve seen too many weld failures from shortcuts.

Q: What’s the best heat treatment for AISI 1045?

A: It depends on your application. For gears, I typically recommend quench and temper to 28-32 HRC. For shafts under bending loads, maybe 25-30 HRC for better toughness.

Q: How do I prevent corrosion?

A: Surface treatment is essential. Phosphating plus paint for most applications. Galvanizing for outdoor use. Don’t rely on the steel alone.

Q: Is medium carbon steel worth the extra cost over mild steel?

A: If you need the strength and wear resistance, absolutely. I’ve seen customers save money long-term by using the right material from the start rather than dealing with premature failures.

Q: How do I choose between 1045 and 4140?

A: For most applications, 1045 is sufficient and more economical. Choose 4140 when you need maximum toughness or are working with large sections that require deep hardening.

Q: Do you provide material certificates?

A: Always. Full mill test reports with every shipment. Traceability is crucial in our business.

Final Thoughts

Medium carbon steel isn’t glamorous. It doesn’t have the corrosion resistance of stainless steel or the strength-to-weight ratio of titanium. But it’s reliable, versatile, and cost-effective. In my experience, these are the qualities that matter most in real-world applications.

The key to success with medium carbon steel is understanding its capabilities and limitations. Use it within its design envelope, treat it properly, and it will serve you well for decades.

At Huaxiao-Alloy, we’re not just suppliers – we’re partners in your success. We bring decades of experience and a commitment to quality that you can count on. When you need medium carbon steel that performs, we’re here to help.

Contact our technical team today to discuss your specific requirements. Let’s solve your material challenges together.