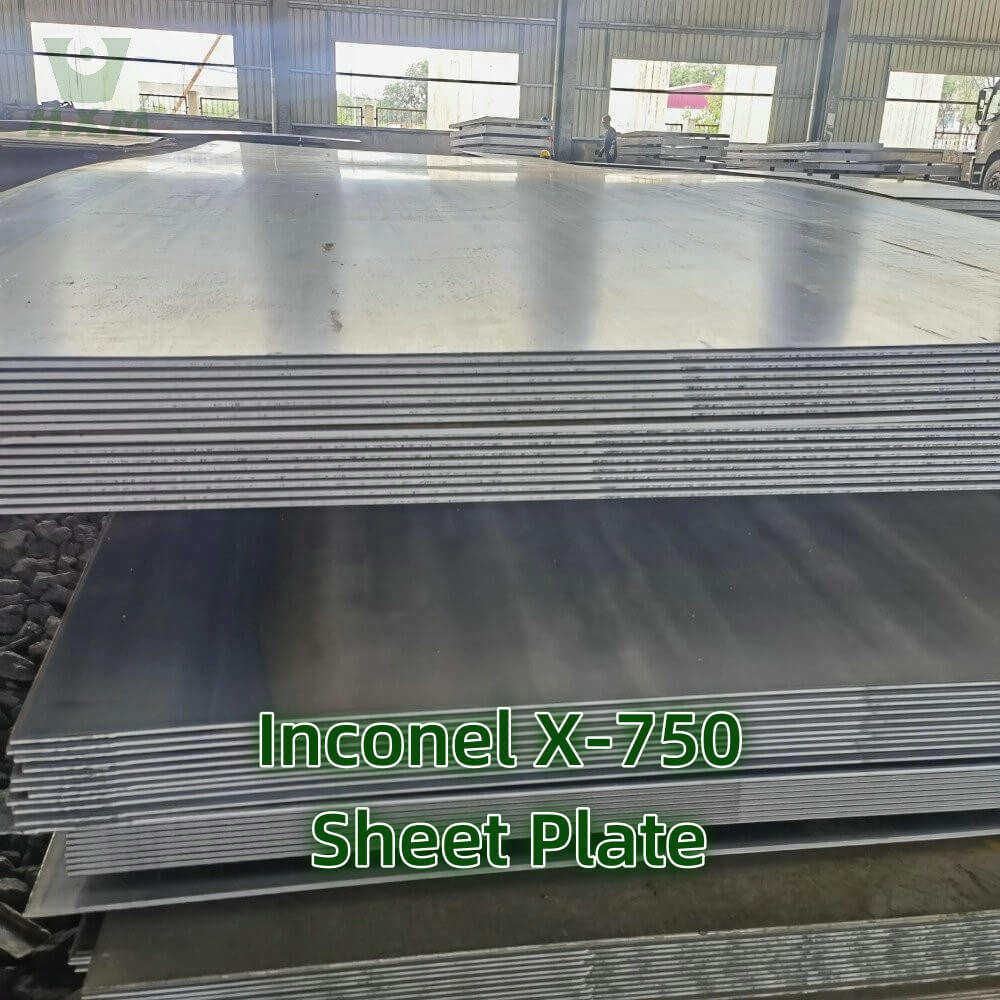

Inconel X-750 Sheet / Plate / Coil

Inconel X-750 is a nickel-chromium alloy strengthened by precipitation hardening, renowned for its high-temperature strength, corrosion resistance, and excellent creep rupture properties. As a premier Inconel X-750 Sheet/Plate/Coil manufacturer, Huaxiao-Alloy supplies this alloy under the following designations:

- UNS N07750

- EN 2.4669

- W. Nr. 2.4669

Huaxiao-Alloy’s Inconel X-750 products meet rigorous international standards for aerospace, energy, and industrial applications:

- ASTM B168 (Sheet/Plate)

- ASTM B637 (Forged Bar/Coil)

- ASME SB168

- AMS 5542

- DIN 17752

Huaxiao-Alloy as a Inconel X-750 Plate supplier ensures compliance with certifications like ISO 9001, AS9100, and NADCAP for aerospace-grade quality.

Available Product Specifications

| Product Form | Thickness (mm) | Width (mm) | Length (mm) | Surface Finish |

|---|---|---|---|---|

| Sheet | 0.5–30 | 600–2500 | 1500–6000 | Cold-rolled, Annealed |

| Plate | 5–120 | 1000–3500 | 2500–10000 | Hot-rolled, Pickled |

| Coil | 0.5–6 | 300–1500 | Custom | Annealed, Polished |

Custom dimensions and tolerances are available upon request from this Inconel X-750 Coil manufacturer.

What is Inconel X-750 material?

Inconel X-750 is a nickel-chromium superalloy specifically strengthened by precipitation hardening. It’s known for its exceptional combination of high strength, outstanding corrosion resistance, excellent oxidation resistance, and good creep resistance at elevated temperatures up to about 815°C (1500°F).

Mechanical Properties

Inconel X-750 delivers exceptional performance in extreme environments:

- Tensile Strength: 1260–1400 MPa

- Yield Strength (0.2% Offset): 700–950 MPa

- Elongation: 15–25%

- Hardness: 300–350 HB

- Density: 8.28 g/cm³

These properties make Huaxiao-Alloy’s Inconel X-750 Sheet ideal for gas turbines, nuclear reactors, and rocket engines.

Chemical Composition

| Element | Ni | Cr | Fe | Ti | Al | C | Mn | Si | Cu |

|---|---|---|---|---|---|---|---|---|---|

| **% Content** | ≥70 | 14–17 | 5–9 | 2.25–2.75 | 0.7–1.2 | ≤0.08 | ≤0.50 | ≤0.50 | ≤0.50 |

The optimized titanium and aluminum content enables age-hardening, a key feature of Huaxiao-Alloy’s Inconel X-750 Plate.

Cross-National Designations

| Country | Standard | Equivalent Grade |

|---|---|---|

| USA | ASTM/ASME | UNS N07750 |

| Europe | EN | 2.4669 |

| Japan | JIS | NCF 750 |

| Germany | DIN | W. Nr. 2.4669 |

| China | GB | GH4145 |

As a global Inconel X-750 Sheet supplier, we guarantee compliance with regional specifications for seamless integration into your supply chain.

Key Characteristics

- High-Temperature Stability: Retains strength up to 815°C (1500°F).

- Oxidation Resistance: Excellent resistance to air oxidation and carburization.

- Stress Rupture Strength: Performs under prolonged stress at elevated temperatures.

- Weldability: Compatible with TIG, MIG, and electron beam welding.

- Fatigue Resistance: Ideal for cyclic thermal and mechanical loading.

These attributes position Huaxiao-Alloy’s Inconel X-750 Coil as a top choice for aerospace and energy sectors.

Applications

- Aerospace: Turbine blades, combustion chambers, thrust reversers.

- Nuclear Power: Reactor core components, control rod mechanisms.

- Oil & Gas: Downhole tools, valve components, flare systems.

- Industrial Gas Turbines: Discs, shafts, and compressor parts.

- Chemical Processing: Heat exchangers, catalyst grids.

Trust Huaxiao-Alloy, a leading Inconel X-750 Plate manufacturer, for mission-critical applications requiring reliability under extreme conditions.

Why Choose Huaxiao-Alloy for Inconel X-750 Sheet / Plate / Coil?

- Decades of Expertise: 25+ years in advanced alloy production and fabrication.

- End-to-End Solutions: Precision machining, heat treatment, and surface finishing.

- Quality Assurance: Full traceability with Mill Test Certificates (MTCs) and third-party testing.

- Global Logistics: Efficient shipping to 60+ countries via air, sea, or land.

- Sustainability: Eco-conscious manufacturing aligned with ISO 14001 standards.

Our Inconel X-750 Sheet supplier team provides 24/7 technical support, including alloy selection and application engineering.

Get Quote Now for Inconel X-750 Sheet / Plate / Coil

FAQs about Inconel X-750

Solution annealing at 1150°C (2102°F) followed by aging at 730°C (1346°F) achieves peak mechanical properties.

Yes, we provide coatings like nitriding or shot peening to enhance wear resistance.

Yes, its high nickel content ensures resistance to sulfide stress cracking.

X-750 offers higher temperature capability (815°C vs. 700°C) but requires stricter heat treatment control.

Standard stock items ship within 1–2 weeks; custom orders require 6–8 weeks.