What is Metal Coating? Industrial Techniques, Materials & Applications Explained

- June 26, 2025

- 9:40 pm

- 111

Metal coating applies protective or functional layers (0.5µm–500µm thick) to substrates like steel, aluminum, or alloys. At Huaxiao-Alloy, we supply coated metals engineered to combat corrosion, reduce friction, enhance conductivity, or enable advanced manufacturing – extending component lifespan by 200–500% in harsh environments.

Comparison Table of Metal Coating Types

| Coating Type | Material | Protection | Typical Substrate | Use Case |

|---|---|---|---|---|

| Galvanizing | Zinc | High (corrosion) | Steel, Iron | Outdoor steel structures |

| Electroplating | Ni, Cr, Au, Ag | Medium to High | Steel, Copper, Brass | Jewelry, electronics |

| Powder Coating | Thermoset polymers | Moderate | Steel, Aluminum | Furniture, machines |

| Anodizing | Aluminum oxide | High (oxidation) | Aluminum | Aircraft, buildings |

| Thermal Spraying | Alloys, ceramics | High (abrasion & heat) | Steel, Inconel, others | Industrial components |

| Phosphate Coating | Manganese/Zinc | Moderate | Steel | Car bodies, tools |

SECTION 1: COATING FUNCTIONS & INDUSTRY DEMANDS

Critical Technical Objectives:

| Function | Technical Metric | Industry Use Case |

|---|---|---|

| Corrosion Resistance | Salt spray resistance (ASTM B117) ≥1,000 hrs | Offshore platforms, automotive chassis |

| Wear Resistance | Hardness ≥800 HV (Vickers) | Mining equipment, hydraulic rods |

| Thermal Protection | Thermal stability ≥1,100°C | Jet engine turbines, exhaust systems |

| Electrical Control | Resistivity 10⁻⁶–10⁹ Ω·cm | Electronics (EMI/RFI shielding) |

| Aesthetic Durability | QUV accelerated weathering >5 yrs | Architectural cladding, consumer goods |

Real-World Impact: Uncoated mild steel in seawater corrodes at 1.5 mm/year; hot-dip galvanizing reduces this to <0.015 mm/year.

SECTION 2: MAJOR METAL COATING TECHNOLOGIES

1. Hot-Dip Galvanizing (HDG)

- Process: Immersion in molten zinc (449°C) → forms Zn-Fe alloy layers (ISO 1461)

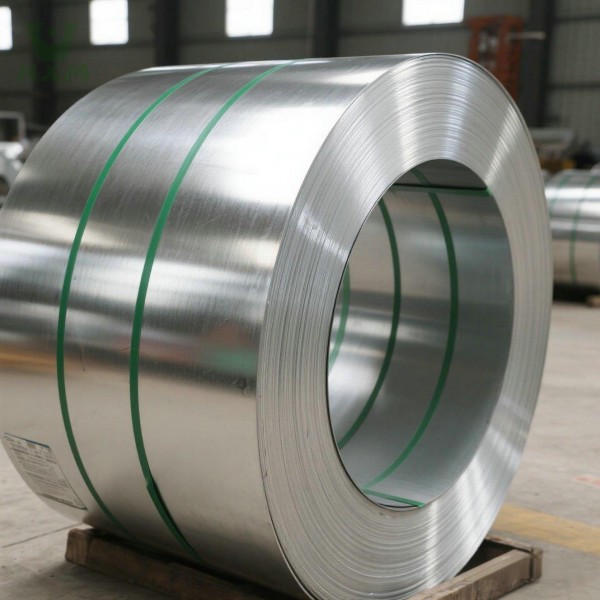

- Huaxiao Product: Z600 HDG Steel Coils (275g/m² coating, ASTM A123)

- Applications: Power transmission towers, highway guardrails

2. Electroplating

- Process: Electro-deposition of metals (Zn, Ni, Cr, Cu) at 1–50µm thickness (ASTM B633)

- Huaxiao Offering: Electrogalvanized Steel (EG) Sheets

- Specs: 20–40g/m² coating, spangle-free finish

- Uses: Electrical enclosures, appliance housings

3. Anodizing

- Process: Electrochemical oxidation → aluminum oxide layer (MIL-A-8625)

- Huaxiao Solution: Anodized 6061/6063 Aluminum Profiles

- Types:

- Decorative: 5–25µm thickness (dyed colors)

- Hardcoat: 50–100µm thickness, hardness 60–70 HRC

- Types:

4. Thermal Spray Coating

- Techniques: HVOF, Plasma Spray, Arc Spray

- Huaxiao Advanced Materials:

- WC-12Co Powder: For abrasive wear resistance (HRC 72)

- NiCrAlY Bond Coats: Oxidation protection >1,000°C

5. Organic/Paint Systems

- Epoxy, PU, Fluoropolymers: Applied via coil coating (ISO 12944)

- Product Highlight: PVDF-Coated Aluminum Coils (40µm)

- Color retention >20 years (AAMA 2605 compliant)

SECTION 3: COATING SELECTION GUIDE BY INDUSTRY

| Sector | Recommended Coating | Huaxiao Product Match |

|---|---|---|

| Oil & Gas | Inorganic Zinc Silicate + Epoxy | Zinc-Aluminum-Mg Sheet (ZAM®) |

| Construction | HDG + Powder Coating | Hot-Dip Galvanized Rebar (BS 6744) |

| Automotive | Electrogalvanized Zn-Ni | EG Steel w/ 10g/m² Coating (JIS G3313) |

| Aerospace | HVOF WC-CoCr | AMS 7877 HVOF Powders |

| Consumer Electronics | Anodizing Type II/III | Hard Anodized 6061 Enclosures |

SECTION 4: HUAXIAO-ALLOY’S COATING EXPERTISE

We bridge material science with industrial execution:

Global Certifications: ASTM, ISO, JIS, EN, MIL-SPEC

Precision Control:

- Coating thickness tolerance: ±2µm (electroplating)

- Surface roughness: Ra 0.8–1.6µm (thermal spray)

Advanced Options: - Magnesium-Zinc Alloy Coatings (MgZn): Salt spray >3,000 hrs (automotive)

- Graphene-Enhanced Epoxy: 7x better corrosion inhibition vs. standard epoxy

Case Study: Wind turbine bolts coated with Huaxiao’s dacromet (Zn-Al flake) exceeded 1,200 hrs salt spray test vs. competitor’s 800 hrs.

Applications of Metal Coatings

Metal coatings are used across various industries to meet functional, safety, and regulatory requirements:

Construction: Roofing sheets, structural beams, fasteners

Automotive: Car bodies, engine parts, wheels

Electrical & Electronics: Connectors, circuit boards, housings

Aerospace: Aircraft parts, turbine blades, structural panels

Oil & Gas: Offshore platforms, pipelines, drilling equipment

Consumer Goods: Kitchen appliances, furniture, decorative hardware

CONCLUSION: ENGINEERING LONGEVITY

Metal coatings are non-negotiable performance multipliers – whether preventing refinery downtime or enabling lighter electric vehicles. At Huaxiao-Alloy, we combine mill-direct metals, advanced coating technologies, and global logistics to solve degradation challenges.

Why Choose Huaxiao Alloy?

At Huaxiao-Alloy, we export a wide range of coated and uncoated metal materials, including:

Galvanized Steel Coils & Sheets (GI)

Prepainted Galvanized Steel (PPGI / PPGL)

Aluminum Coils with Anodized or Painted Surface

Electroplated Steel Products

Custom Surface Treatments Available on Request

We support OEM production, international logistics, and third-party inspections to ensure the highest product quality and consistency.

Optimize component performance with precision-coated metals:

➤ Request Coated Metal Samples (HDG, EG, ZAM, Anodized)

➤ Download Industrial Coating Selection Guide (Includes ASTM/ISO cross-reference)

➤ Consult Our Engineers – Solve specific corrosion/wear challenges

[REQUEST COATING DATASHEETS] • [CONTACT COATING SPECIALISTS] • [GET QUOTE WITHIN 24H]

Coating generally refers to applying a protective layer (can be metallic or non-metallic), while plating specifically involves metal-on-metal deposition, often using electrochemical methods.

Yes, though stainless steel is corrosion-resistant by itself, coatings such as powder coating or electropolishing may be used for additional protection or aesthetics.

Consider your environmental conditions (humidity, temperature, chemicals), aesthetic needs, durability expectations, and industry standards. Our technical team can help you select the ideal solution.