Non-Grain Oriented Electrical Steel (NGOES)

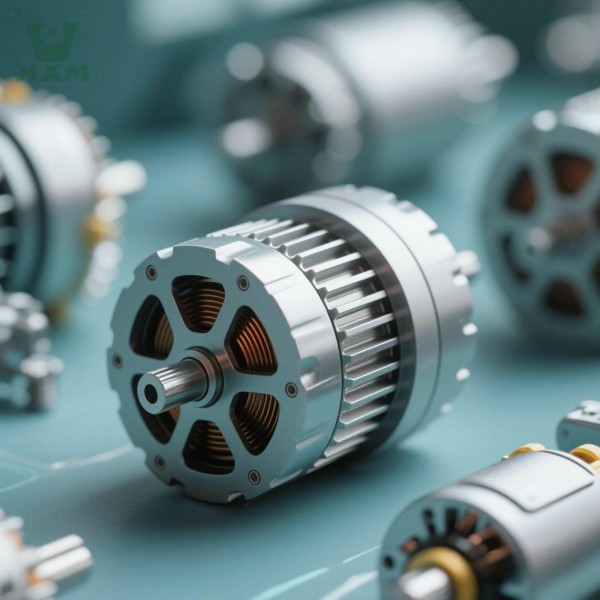

Versatile magnetic steel for motors, generators, and rotating machines.

Power the next generation of electric mobility and industrial automation with Huaxiao-Alloy’s premium Non-Grain Oriented Electrical Steel (NGOES). Engineered for superior magnetic performance in all directions, our cold-rolled silicon steel minimizes core losses while maximizing permeability and saturation flux density—critical for boosting efficiency in rotating electromagnetic applications.

Highest Quality Steel

Quick Delivery

Professional Service

Flexible payment options

Key Properties & Grades of Non-Grain-Oriented Electrical Steel (NGOES)

- Material: Cold Rolled Non-Grain Oriented Electrical Steel (NGOES / CRNGO)

- Grades: Standard & High-Performance (e.g., M400-50A, M330-50A, 35H300, 50H800, JNEH8000, JNEH9000, ASTM A848, EN 10106)

- Core Loss (P1.5/50): Ultra-low (<4.0 W/kg @1.5T/50Hz) to commercial grades (<8.0 W/kg). Full P1.7/50 & P1.0/400 data available.

- Thicknesses: 0.35mm (ultra-low loss), 0.50mm (standard), 0.65mm (structural)

- Coating: C5 / C6 insulation coatings (organic, inorganic), annealed or unannealed

- Magnetic Flux Density (B50): Up to 1.70 Tesla

- Key Benefits:

→ Low hysteresis & eddy current losses

→ High permeability across all directions

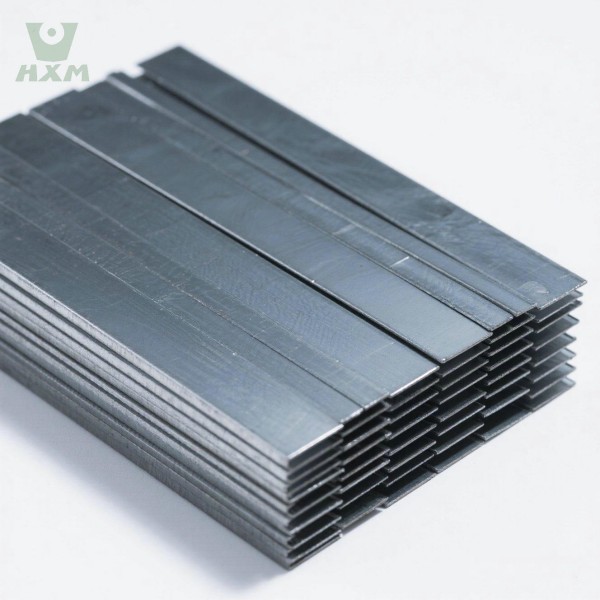

→ Superior punchability & stackability

→ Consistent material homogeneity

→ Customizable coating resistance & adhesion

(Available Forms)

- Sheet: Widths 600mm to 1250mm

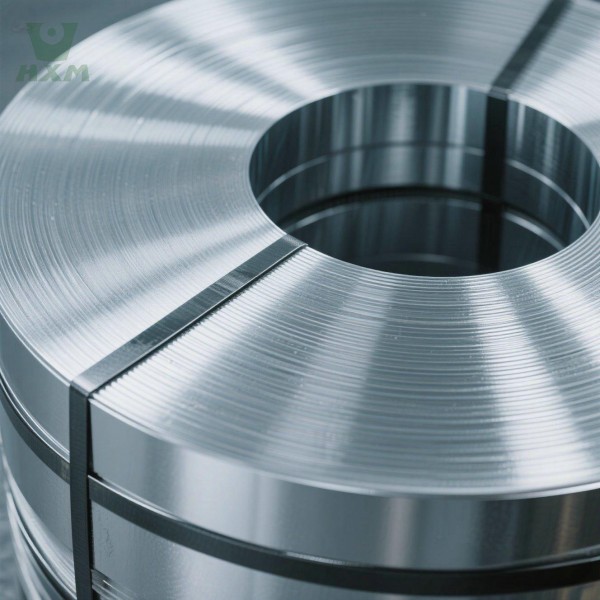

- Coil: ID 508mm / OD up to 1800mm (2-10 MT coils)

- Custom slitting & cut-to-length available

What is Non-Grain-Oriented Electrical Steel (NGOES)?

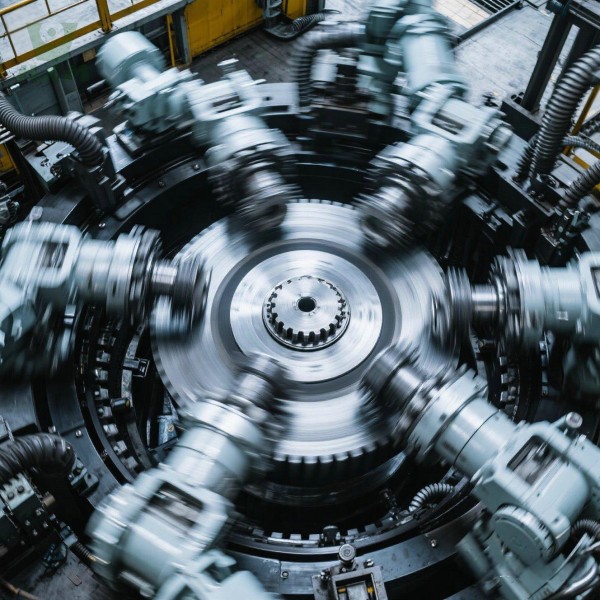

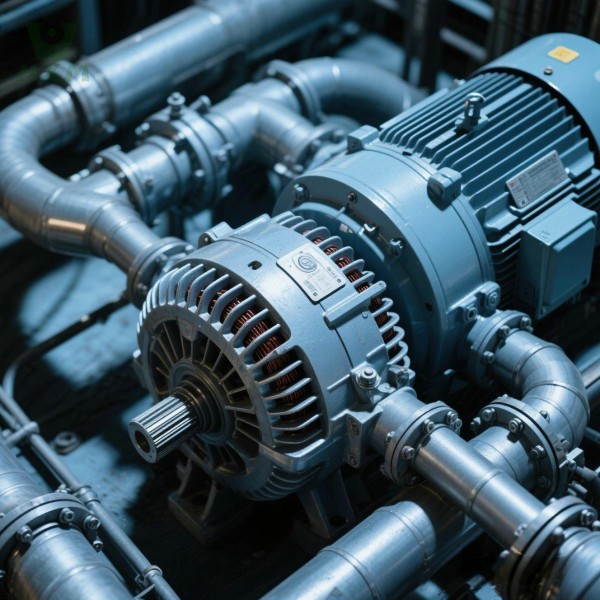

Non-Grain-Oriented Electrical Steel (NGOES) is a type of electrical steel that exhibits similar magnetic properties in all directions. Unlike grain-oriented electrical steel, NGOES does not have a preferred magnetic orientation, making it ideal for applications involving rotating machines such as electric motors, generators, and alternators.

At Huaxiao-Alloy, we supply high-performance NGOES materials with consistent thickness, smooth surface finish, and optimized silicon content for high electrical resistivity and reduced core loss.

Specifications (Customizable on request)

Property | Typical Range |

Silicon Content | 0.5% – 3.5% |

Thickness | 0.35 mm – 0.65 mm |

Core Loss (W/kg) @ 1.5 T | ≤ 6.0 depending on grade |

Magnetic Induction (B50) | ≥ 1.65 T |

Coating Type | C-3, C-5, or customized |

Standard | IEC 60404-8-4, ASTM A677, JIS C2552 |

Delivery Form | Coils, Slit Coils, Sheets, Laminations |

Key Features of NGOES:

- Isotropic Magnetic Properties: Uniform magnetic performance in all directions

- High Electrical Resistivity: Minimizes eddy current losses

- Excellent Surface Insulation: Suitable for punching and stacking

- High Stamping Resistance: Good mechanical properties for lamination manufacturing

- Wide Thickness Range: Customizable for different end-use applications

Applications of NGOES:

Huaxiao-Alloy provides NGOES for diverse industries requiring dynamic magnetic performance:

- Electric Motors: Widely used in appliances, industrial drives, and HVAC systems.

- Automotive Motors: For electric vehicles and hybrid systems requiring low noise and high efficiency.

- Generators: For consistent performance in power generation applications.

- Alternators & Ballasts: Effective under rapid magnetic field reversals.

- High-Speed Rotating Equipment: Where mechanical strength and stable magnetic flux are essential.

Coatings: More Than Insulation

C6 ceramic coatings withstand >750°C short-term temps in oil-cooled stator cores—critical for 800V architecture motors pushing 200+ kW/L power density.

(Case Study: 0.35mm vs. 0.50mm in 200kW IPM Motor)

| Parameter | 0.50mm M330-50A | 0.35mm JNEH8000 |

|---|---|---|

| Core Loss (P1.0/400) | 32 W/kg | 24 W/kg |

| Peak Torque | 390 Nm | 420 Nm |

| WLTP Range Gain | Baseline | +5.3% |

(Huaxiao-Alloy’s Role)

We supply NGOES certified to automaker specs like Volkswagen VW 90330, GM GMW3094, and GB/T 2521 (China):

- Full traceability back to integrated mills

- E-coat compatibility validation reports

- Slit edge burr control ≤0.02mm

Why Choose Huaxiao-Alloy for NGOES Supply?

- Global Export Expertise: Long-term supplier to Europe, South America, and Southeast Asia.

- Precision Slitting and Coating: High-quality lamination-friendly materials.

- Flexible Order Quantities: Supporting both trial orders and bulk production.

- Technical Support: Engineering consultation and customized product development.

- Traceability & Certifications: Mill test reports and ISO/SGS compliance provided.

Available Grades (Examples):

Grade Standard | Grade Name | Description |

ASTM A677 | M15, M19, M22, M27 | Non-oriented silicon steel for motor and generator cores |

JIS C2552 | 50A470, 50A600 | Japanese non-oriented electrical steel grades |

IEC 60404-8-4 | NO20, NO30, NO35 | International standard NGOES |

Packaging & Delivery

- Horizontal or vertical eye-to-sky packaging

- Clear identification with grade, thickness, coating, and origin

- International shipping with full compliance documentation

Contact Huaxiao-Alloy Today

If you’re sourcing NGOES for industrial manufacturing or electric mobility, contact Huaxiao-Alloy for technical specifications, pricing, and delivery options tailored to your needs.

Email: [email protected]

Website: www.huaxiao-alloy.com